A Guide to Choosing the Perfect Heavy Duty Garage Workbench in UK

In the bustling world of industrial garages, where efficiency, organisation, and durability are paramount, the importance of a heavy-duty garage/workshop workbench cannot be overstated. These industrial workbenches are the backbone of a well-structured workspace, providing essential support for various tasks and functions. Let's explore why an industrial garage requires a heavy-duty boltless workbench and how to choose the right garage workbench.

Let’s Start by Assessing Your Needs and Space

Selecting the proper garage workbench is critical for optimising your workspace's functionality and efficiency. However, before making a choice, assessing your specific needs and available space is imperative. Here are some guidelines to help you evaluate essential factors such as size, weight capacity, and storage requirements:

- Available Space:

Begin by measuring the available space in your garage. Consider both the dimensions of the area where you plan to place the workbench and the overall layout of the workspace. Ensure that the workbench won't obstruct walkways or impede workflow.

- Purpose and Tasks

Determine the primary tasks you'll be performing on the workbench. Are you engaging in heavy-duty tasks like woodworking or automotive repairs, or is it primarily for lighter tasks like assembling and packaging? This assessment will influence the size and durability needed.

- Size of the Workbench:

The workbench size should align with the tasks you'll be performing. A larger work surface provides ample space for tools and materials for industrial or heavy-duty applications. Smaller workbenches are suitable for more compact areas or lighter tasks. The size chart below shows how tall most garage workbenches are -

Common Size Chart of Heavy Duty Workbenches in UK

|

Size |

Width (cm) |

Depth (cm) |

Height (cm) |

|

Small |

61 - 91 |

46 - 61 |

86 - 91 |

|

Medium |

122 - 152 |

61 - 76 |

86 - 91 |

|

Large |

183 - 244 |

61 - 91 |

86 - 91 |

|

Extra Large |

244 - 305+ |

76 - 91+ |

86 - 91 |

- Weight Capacity:

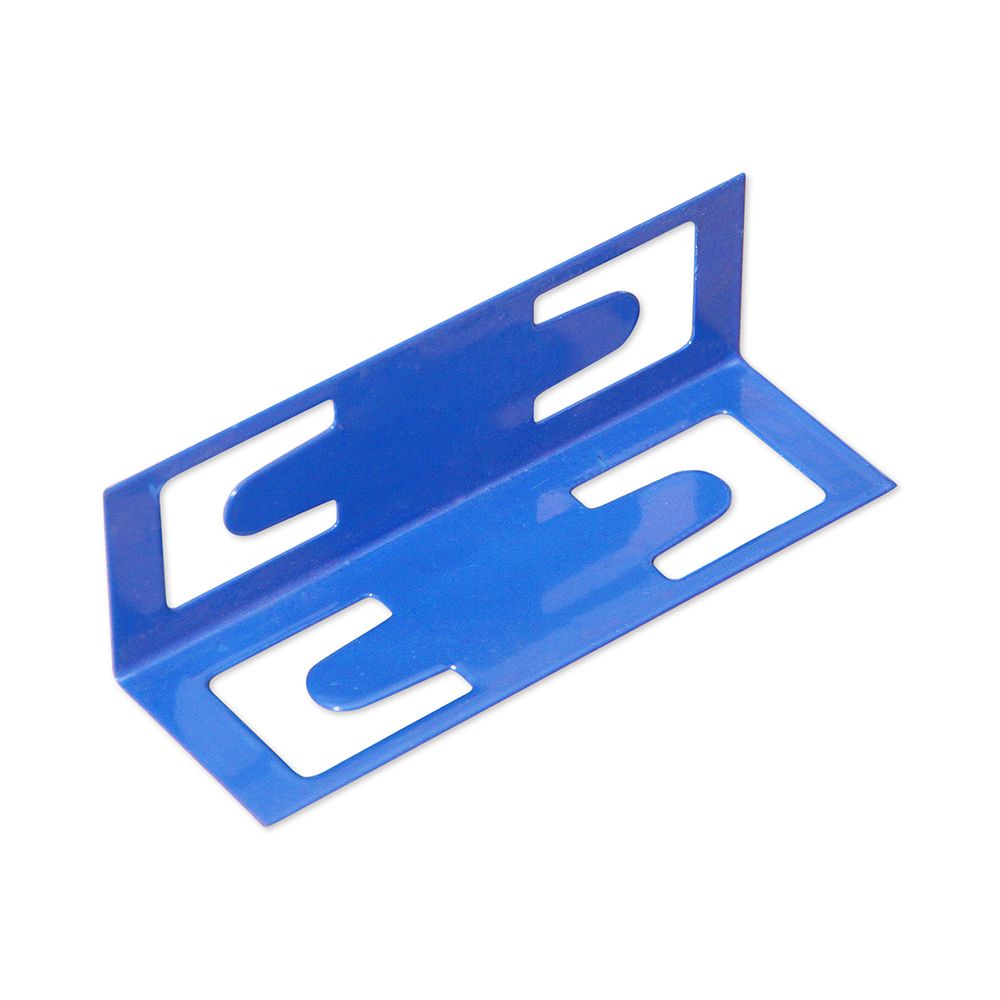

Consider the weight capacity of the workbench. Heavy-duty tasks demand a higher weight capacity to ensure stability and safety. Evaluate the maximum load your workbench will need to support and choose accordingly. G-Rack’s 2-tier boltless heavy duty workbenches can hold up to 256 Kg of weight.

Learn more: How Much Weight Can You Put on Our Shelves?

- Material and Durability:

Evaluate the materials used in constructing the workbench. Heavy-duty workbenches are typically made from steel or hardwood, known for their durability and longevity. Ensure that the materials can withstand your tasks' demands and your garage's environmental conditions. G-Rack’s boltless workbenches have long-lasting rust-resistant coating to metal work along with moisture-resistant MDF shelves.

- Storage Requirements:

Assess your storage needs. Consider workbenches with built-in drawers, shelves, or pegboards if you require quick access to tools. These features help keep your workspace organised and efficient.

- Mobility Needs:

Determine if mobility is necessary. Some workbenches come with casters, allowing you to move them around the garage. This can be beneficial if you need flexibility in your workspace layout.

- Budget Considerations:

Set a budget for your workbench purchase. While quality and durability are essential, 2-tier boltless workbench options are available on G-Rack to suit various price ranges. Prioritise quality over cost, as a well-built workbench is a long-term investment in your garage's efficiency.

By carefully evaluating these factors and aligning them with your specific needs and available space, you can make an informed decision when selecting a garage workbench. This ensures that your workbench fits seamlessly into your industrial garage and enhances productivity and organisation in your workspace.

Types of Garage Workbenches

Garage workbenches come in various types to cater to different needs and preferences. Let's explore three common types: freestanding, wall-mounted, and mobile workbenches, along with their respective pros and cons:

|

Type of Workbench |

Pros |

Cons |

|

Freestanding Workbenches |

Stability: Freestanding workbenches are inherently stable and robust, making them suitable for heavy-duty tasks and tools. Versatility: They can be placed anywhere in the garage and rearranged as needed, providing flexibility in workspace organisation. Storage: Many freestanding workbenches come with built-in storage options like drawers and shelves for easy tool access. |

Space Requirement: They occupy a fixed space in the garage, which may limit floor space for other activities. Not Ideal for Small Garages: In smaller garages, freestanding workbenches can make the space feel cramped. |

|

Wall-Mounted Workbenches |

Space-Saving: Wall-mounted workbenches are excellent for smaller garages or when you want to maximise floor space. Customisable Height: You can mount them at your preferred height for ergonomic working conditions. Easy to Clean: Since they are off the floor, cleaning underneath is straightforward. |

Weight Limitation: Wall-mounted workbenches have weight limits, so they may not be suitable for heavy-duty tasks. Permanent Location: Once installed, they are less flexible in terms of relocation within the garage. Limited Storage: Storage options are usually limited compared to freestanding workbenches. |

|

Mobile Workbenches |

Portability: Mobile workbenches come with wheels, allowing you to move them around as needed. This is ideal for versatile workspaces. Compact Storage: Some models fold or collapse for easy storage when not in use. Multi-Purpose: They can serve as both a workbench and a tool cart, providing convenience. |

Weight Limitation: Like wall-mounted workbenches, mobile versions may have weight limitations. Less Stability: They may not be as stable as freestanding workbenches, especially for heavy tasks. Limited Work Surface: The work surface area may be smaller compared to freestanding alternatives. |

|

Cabinet Workbench |

More Storage: Extensive storage options, including drawers, shelves, and cabinets. Decluttering: Organised tool storage for easy access and clutter reduction. Ease of Maintenance: Concealed workspace when not in use, maintaining a tidy appearance. |

Space Restricting: Limited workspace surface area compared to some other workbench types. Heavy: May be heavy to move or relocate due to added storage components. |

|

Adjustable Height Workbench |

Customisable: Ergonomic working conditions, allowing customisation of the workbench height. Best for heavy-duty working: Suitable for heavy-duty work due to robust construction. |

Costly: Price may be higher compared to non-adjustable workbenches. Complex Assembly: May require more complex assembly compared to some other types. Less Storage Space: Offers less built-in storage space compared to certain freestanding models. |

Watch G-Rack’s Workbench Assembly Video

Heavy-Duty Boltless Workbench Materials and Construction

Considering the materials and construction of a workbench is crucial because it directly impacts its durability, stability, and maintenance requirements. Different materials offer distinct advantages and considerations. Here's an overview of common workbench materials and their key factors to consider:

- Wood

Durability: Wood Workbenches are sturdy and can withstand moderate to heavy loads, making them suitable for various tasks. However, the durability depends on the type of wood used.

Stability: Woodwork Benches provide good stability, especially when constructed with solid hardwoods. They absorb vibrations and offer a comfortable working surface.

Maintenance: Wood requires regular maintenance to prevent moisture damage, warping, and splintering. A protective finish, like varnish or polyurethane, helps maintain its appearance and lifespan.

- Steel

Durability: Steel workbenches are exceptionally durable and can withstand heavy loads and rough use. They are often chosen for heavy-duty tasks.

Stability: Steel workbenches are extremely stable, making them suitable for tasks that require minimal vibrations.

Maintenance: Steel is resistant to moisture and damage but can rust in humid environments. Regular rust prevention measures, such as painting or coating, are necessary.

- Composite Materials

Durability: Composite materials often combine wood fibres with resins or plastics and offer good durability. They are resistant to moisture and warping.

Stability: Composite materials provide stability and can be engineered to absorb vibrations, similar to solid wood.

Maintenance: They typically require minimal maintenance compared to wood. Cleaning and occasional refinishing may be necessary, depending on the composite material used.

When selecting a garage workbench, consider the tasks you'll be performing, the weight of tools and materials you'll be working with, and your garage environment. Each material has its strengths, so choose one that aligns with your needs for durability, stability, and maintenance. Additionally, pay attention to the workbench's construction, including the joinery methods and reinforcements. A well-constructed boltless heavy-duty workbench will offer better overall performance and longevity, regardless of the chosen material.

Boltless Workbench Features and Accessories

When choosing a heavy-duty workbench for your garage or workshop, it's essential to consider various features and accessories that can enhance its functionality and make it more versatile. Here are some important features and additions to consider:

- Adjustable Height:

- An adjustable height workbench allows you to customise the height to suit different tasks and user preferences.

- It is ideal for ergonomic working conditions, as it reduces strain on your back and shoulders.

- It helps accommodate various types of work, from woodworking to metalworking.

- Built-in Storage:

- Built-in storage options like drawers, shelves, and cabinets provide convenient and organised tool storage.

- Reduces clutter in your workspace and ensures that your tools and materials are easily accessible.

- Allows you to keep your garage or workshop table tidy and well-organised.

- Pegboards and Wall Panels:

- Pegboards and wall panels with hooks and hangers are excellent for hanging tools and small accessories.

- Maximises vertical space and keeps frequently used tools within arm's reach.

- Provides a clear view of your tools for quick access and inventory checks.

- Power Outlets and USB Ports:

- Workbenches with integrated power outlets and USB ports allow you to plug in power tools, chargers, and other devices directly at the bench.

- It eliminates the need for extension cords and provides a convenient power source.

- Vices and Clamps:

- A built-in vice or clamp can secure workpieces firmly, making performing tasks like cutting, drilling, and sanding easier.

- Ensures accuracy and safety when working with various materials.

- Tool Holders and Racks:

- Tool holders, racks, and trays can be attached to the workbench to keep hand tools and accessories organised and within reach.

- Increases efficiency by reducing the time spent searching for tools.

- Overhead Lighting:

- Integrated overhead lighting or the option to attach task lighting enhances visibility and ensures proper workspace illumination.

- It reduces eye strain and allows you to work safely and accurately.

- Casters or Mobility Options:

- Workbenches with casters or mobility features make moving the bench around your garage or workshop easy.

- It offers flexibility in reorganising your workspace or taking your workbench to different project locations.

- Tool Well or Trench:

- Some workbenches feature a tool well or trench along the perimeter, providing a convenient place to keep small parts and tools.

- It prevents items from rolling off the bench and getting lost.

- Materials and Durability:

- Choose a boltless garage workbench made of durable steel, hardwood, or composite materials, depending on your specific needs and preferences.

- Ensure the workbench is sturdy enough to handle the weight of heavy tools and materials.

When selecting a workshop heavy-duty workbench, prioritise the features and accessories that align with your typical tasks and workflow. Consider the available space in your garage or workshop and how the workbench's design and accessories will optimise your workspace for efficiency and convenience.

Maintenance and Care of Garage Workbenches

Proper maintenance and care of your garage workbench are essential to ensure its longevity and optimal performance. Here are some tips and guidelines to help you keep your workbench in great condition:

- Regular Cleaning

Clean your workbench regularly to remove dust, debris, and spills. Use a damp cloth or sponge and mild, soapy water for most materials.

- Preventive Measures

Use a protective mat or tray under heavy or messy projects to prevent stains and damage to the workbench surface. Avoid dropping heavy objects on the workbench to prevent dents and scratches.

- Wood Workbenches

Apply a protective finish such as varnish or polyurethane to wooden surfaces to prevent moisture damage, warping, and splintering. Inspect for any loose or splintered wood and sand them down or repair them as needed.

- Steel Workbenches

Check for rust regularly, especially in humid environments. Remove any surface rust with a wire brush and apply rust-resistant paint or coating. Keep the workbench dry to prevent moisture-related issues.

- Composite Workbenches

Composite materials are generally low-maintenance but should be cleaned regularly to prevent dirt buildup. Follow the manufacturer's recommendations for cleaning and maintenance.

- Adjustable Mechanisms

If your workbench has adjustable height mechanisms, lubricate them periodically to ensure smooth operation.

- Tool Storage

Organise and store your tools properly to prevent clutter on the workbench, which can lead to damage.

- Electrical Outlets

If your workbench has built-in power outlets, ensure they are in good working condition and free from dust or debris.

- Lighting

To maintain proper illumination, check and replace any task lighting or overhead lights.

- Mobility Features

If your workbench has casters or wheels, ensure they are in good working condition and that the locking mechanisms work correctly.

- Inspect Regularly

Periodically inspect your workbench for any loose bolts, screws, or parts needing tightening or replacement.

- Read G-Rack’s Instructions

Always follow the G-Rack's assembly, care and maintenance instructions for your specific workbench model.

By following these maintenance and care guidelines, you can extend the life of your garage workbench and ensure that it remains a reliable and functional workspace for your projects. Regular upkeep helps prevent costly repairs or replacements in the long run.

G-Rack’s Heavy-Duty Workbench Offerings

G-Rack provides an excellent solution for garage organisation with its versatile workbench offerings. Our workbenches come equipped with integrated shelving and workbench shelves, combining functional workspace with efficient storage solutions. These thoughtfully designed workbenches ensure a dedicated area for various tasks while keeping your tools, equipment, and supplies neatly organised on the attached shelves. G-Rack's workshop workbench with shelving and workbench shelves is the perfect choice for individuals and industries looking to maximise their garage space, create an efficient workspace, and maintain a clutter-free environment for all their projects.