How To Rightly Measure Shelving & Racking Upright Connectors For Shelving Units?

Proper measurement is crucial when it comes to shelving unit joints and racking upright connectors as it directly impacts the stability and functionality of the entire storage system. Accurate measurements ensure the connectors fit precisely, creating a robust and secure framework. The stability of shelving connectors and racking connectors relies on the precise alignment of upright connectors. Incorrect measurements may lead to uneven weight distribution, compromising the structural integrity of the entire unit. This can result in shelves sagging, potential collapse, and a heightened risk of stored items. Functionality is another critical aspect influenced by accurate measurements. Well-fitted upright connectors enable the seamless integration of shelves, facilitating smooth assembly and disassembly. Properly measured shelving connectors ensure the system can accommodate varying load capacities, providing versatility in storage options. In industrial settings, where shelving and racking are often subject to heavy loads, adherence to precise measurements becomes even more paramount. It not only promotes safety but also optimises the utilisation of storage space.

In this blog, you will learn the importance of accurate measurements in shelving and racking upright connectors, which cannot be overstated, as it forms the foundation for a reliable, safe, and efficient storage solution.

Understanding Shelf & Rack Upright Connectors

Upright connectors play a pivotal role in the stability and functionality of shelving units, serving as critical components in warehouse pallet racking systems. These connectors are essential for creating a robust and secure framework that supports the weight of shelves and stored items. The various types of shelving connectors contribute to seamless maintenance and customisation, ensuring optimal functionality and durability of the entire shelving unit.

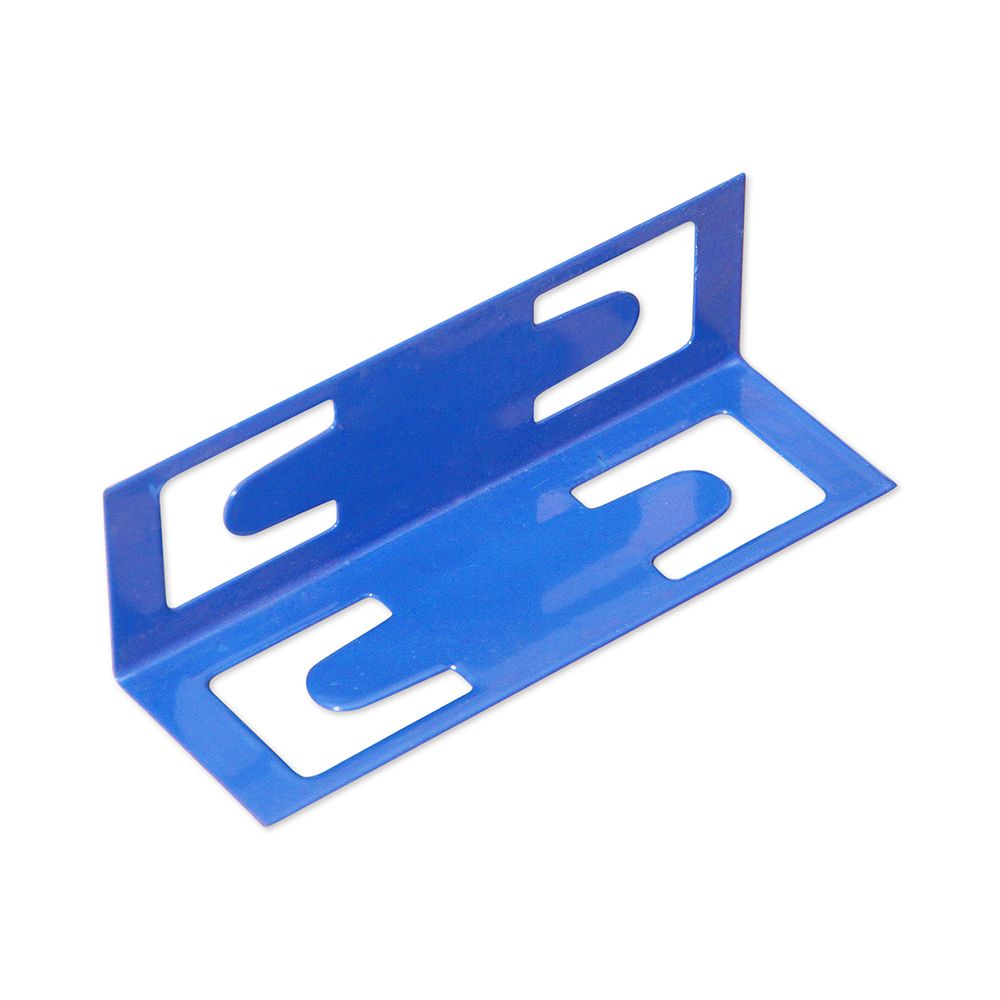

Buy Boltless Shelving Upright Connectors (Pack of 4)- Metal Coated

Sturdy Shelving Upright Connectors

The importance of sturdy upright shelving connectors cannot be overstated. They are specifically designed to ensure a solid and secure connection between the vertical uprights, which are essentially the backbone of any shelving structure. These shelving connectors are engineered with heavy-duty materials that can withstand substantial loads and keep the uprights firmly in place. By doing so, they contribute significantly to the overall stability of the shelving system, which is crucial for the safe and efficient storage of items. Without these connectors, the vertical uprights would be prone to wobbling and collapsing, which could cause damage to the items being stored and pose a risk to individuals working around the shelving unit. Therefore, it is essential to invest in high-quality shelving upright connectors to ensure any shelving system's longevity, safety, and structural integrity.

Buy Bay Connectors (Pack of 2)

Bay Connectors

Bay connectors play a pivotal role in the overall structural integrity of a shelving unit. They are designed to join individual bays of shelving horizontally, providing stability and ensuring the entire system functions as a cohesive unit. Without reliable bay connectors, the shelving unit may be unable to support the intended load, potentially compromising stability and posing a risk to the users. Therefore, it is crucial to choose high-quality bay connectors capable of withstanding the weight and stresses of the load to guarantee a safe and dependable shelving system.

These warehouse pallet racking components enable seamless customisation by offering a range of connectors, from sturdy upright connectors to reliable bay connectors. This allows for the adaptation of shelving units to specific storage needs and ensures that the system can be easily maintained and modified over time. The emphasis on optimal functionality and durability underscores the importance of these connectors in creating efficient and long-lasting warehouse storage solutions.

Tools Needed To Measure Shelving & Racking Connectors

Measuring upright connectors accurately is crucial for ensuring the stability and functionality of shelving and racking systems. The following is a detailed list of essential tools required for measuring upright connectors:

Tape Measure

A reliable tape measure is fundamental for obtaining precise measurements of the length, width, and height of the upright connectors. Choose a tape measure with clear markings and a locking mechanism to secure measurements in place.

Callipers

Callipers are useful for measuring the diameter of bolts, holes, or other critical dimensions on the connectors. Digital or dial callipers provide accurate readings and are especially beneficial for fine measurements.

Combination Square

A combination square is versatile for ensuring that the angles and edges of the upright connectors are square and aligned correctly. It aids in maintaining the overall squareness of the shelving unit.

Level

A level helps ensure that the upright connectors are plumb and that shelves will be even. It is essential to maintain the connectors' vertical alignment to prevent tilting or leaning of the shelving system.

Spirit Level or Bubble Level

A spirit level, or bubble level, is essential for checking horizontal alignment. It ensures that the connectors are level, preventing any uneven distribution of weight on the shelves.

Straight Edge

A straight edge confirms that the upright connectors are straight and not warped. It helps in identifying any deviations that could affect the stability of the shelving unit.

Marker or Pencil

Markers or pencils are essential for making clear and accurate marks on the connectors. These marks serve as reference points for cutting or drilling, ensuring precise installation.

Safety Equipment

Safety gear, including gloves and safety glasses, is crucial when working with tools. These protect against potential injuries and ensure a safe measuring and installation process.

Notebook and Pen

Keeping a notebook and pen handy allows you to record measurements and any other important details during the measuring process. This documentation is valuable for accurate assembly and future adjustments.

Power Tools (if needed)

Depending on the specific connectors and shelving system, power tools such as a drill or an impact driver may be necessary for drilling holes or securing bolts efficiently.

A well-equipped toolkit ensures that you can measure upright connectors accurately and contribute to the overall stability and functionality of the shelving or racking system.

Step-by-Step Measurement Guide

Understand Your Storage Solution:

For accurate measurements, it's crucial to have a good understanding of the storage solution you choose. Whether you go for rivet shelving, roll-formed racking, or wire shelving, it's crucial to familiarise yourself with the specific features of each connector. Take note of their shape, size, and material, and understand how they contribute to the adjustability of the system. This knowledge will not only help you take precise measurements but also enable you to make the necessary adjustments to the storage solution whenever required.

Gather Tools

Before starting the task, it is important to ensure that you have all the necessary tools and equipment readily available. You will need a tape measure to take accurate measurements, callipers to measure the thickness of the material, a combination square to check for squareness, a level to ensure that the surface is level, a straight edge to check for straightness, a marker to mark the material, and appropriate safety gear such as gloves and eye protection. All these tools will help you complete the task efficiently and safely.

Select Your Storage Configuration:

When selecting the appropriate shelving or racking configuration for your storage needs, it's important to consider several factors. Take into account the adaptability of various designs, such as rivet shelving or roll-formed racking, which offer ease of assembly and reconfiguration. These configurations provide the flexibility to modify your storage space as your needs evolve. Additionally, consider the specific storage requirements for your items, such as weight capacity and size restrictions, to ensure that your chosen shelving or racking configuration can accommodate them. By taking these considerations into account, you'll be able to select a shelving or racking configuration that is both functional and efficient for your unique storage needs.

Measure Inventory:

Measure the width, height, and depth of your products. This provides crucial information for determining the appropriate shelving configuration. Determine the overall width of the shelving area, accounting for the horizontal space available for storage. Common widths are 36", 42", and 48". Measure the depth, which is the distance from the rear of the shelf to the front face. Standard steel shelving depths include 12", 18", and 24".

If configuring or ordering a pallet racking system, measure standard pallet sizes (e.g., 40" ×40", 48" ×48") and determine the appropriate beam length for your palletised merchandise.

Consider Adjustability:

As you review different shelving options for your needs, it's important to pay attention to any design features that offer flexibility. For instance, if you're considering rivet shelving, you may want to note the keyhole-shaped slots on the uprights, which make it easy to adjust shelf heights without requiring any tools. Alternatively, if you're looking at wire shelving, keep in mind the locking grooves on the posts, which enable you to make incremental changes to the shelf heights as needed. Being aware of these details can help you choose a shelving system that will work well for your specific requirements and give you greater flexibility in arranging your storage space.

Ensure Precision:

Accurate measurements are crucial for any building project. To ensure precision, it's important to use the appropriate tools. The tape measure and callipers are ideal for measuring length, width, and diameter. When checking angles and edges, the combination square is the perfect tool to ensure the connectors align correctly. To ensure that everything is vertically aligned, use a level. In addition, the straight edge is an essential tool to identify any warping. When marking connectors, it's important to use a marker or pencil to make clear and precise marks.

Document Measurements:

When measuring a shelving or racking system, make sure to take note of all the measurements, including the width, height, and depth of the shelves themselves. Also, be sure to record any specific dimensions of the upright connectors that will be used to secure the system in place. It's important to be as detailed as possible to ensure accuracy and avoid any potential issues during installation.

Safety First:

When using power tools for installation, it is crucial to prioritise safety by wearing appropriate safety gear. This includes but is not limited to protective eyewear, gloves, and footwear. Additionally, it is important to ensure that the work area is well-lit, free of clutter, and that all tools are in good working condition before beginning any project. Taking these precautions can help to prevent accidents and ensure a safe working environment.

Ensure accurate measurement of upright connectors for safe and efficient inventory storage. Regularly review and update configurations to adapt to changing storage requirements.

Read more: Optimise Your Space: The Benefits of Racks And Shelving Systems

Common Mistakes to Avoid

Common errors in measuring upright connectors can lead to unstable shelving or racking systems and compromise overall storage efficiency. Here are some frequent mistakes and insights on how to avoid them for a successful installation:

Inaccurate Measurements

Use high-quality measuring tools like tape measures, callipers, and combination squares. Double-check all measurements to ensure accuracy. Rushed or imprecise measurements can lead to misalignments and instability.

Neglecting Clear Documentation

Record all measurements systematically in a notebook or digital document. This documentation is crucial during installation and future adjustments, preventing confusion and ensuring consistency.

Ignoring Adjustability Features

Understand the design of the upright connectors, especially if they have adjustable features like keyhole slots or locking grooves. Failing to utilise these features may limit the adaptability of the shelving system.

Disregarding Load Capacity

Consider the load capacity of the connectors and shelves. Overloading can lead to structural issues. Consult the manufacturer's guidelines to ensure the connectors support the intended weight.

Neglecting Vertical Alignment

Use a level to confirm that the upright connectors are vertically aligned. Ignoring this aspect can result in a shelving unit that leans or tilts, risking a collapse.

Forgetting About Clearances

Account for clearances around the shelving unit, including vertical and horizontal spaces. Consider these clearances to avoid difficulties in accessing or storing items.

Overlooking Shelving Unit Depth

Measure the depth of the shelving unit accurately. Neglecting this can result in shelves that are too shallow or too deep, affecting the functionality and aesthetics of the storage system.

Skipping Safety Precautions

Always wear appropriate safety gear, especially when using power tools for installation. Neglecting safety precautions can lead to injuries and delays in the installation process.

Assuming Standard Sizes

Don't assume that all upright connectors are of standard sizes. Measure each component individually, as variations may exist, especially in custom-designed shelving or racking systems.

Disregarding Material Compatibility

Ensure that the upright connectors are compatible with the material and design of the shelves. Mismatched materials can lead to instability and compromise the overall durability of the system.

Ignoring Environmental Considerations

Consider the environmental conditions where the shelving unit will be installed. Factors like temperature, humidity, and potential exposure to corrosive substances can impact the longevity of the connectors.

By being mindful of these common errors and following the avoidance tips, individuals can significantly enhance the accuracy of their measurements, leading to a successful and secure installation of shelving and racking upright connectors. Regular maintenance and periodic reassessment of the storage system ensure continued stability and efficiency.

Read More: The Benefits of Corner Shelving

Importance of Accurate Measurements

Inaccurate measurements in shelving units can have severe consequences, affecting stability, safety, and overall functionality. These repercussions can compromise the integrity of the storage system and pose risks to the stored items and individuals interacting with the shelves. Here are the key consequences:

Instability:

Inaccurate measurements often lead to misalignment of upright connectors, compromising the overall stability of the shelving unit. This instability can result in the shelves being unable to bear the intended load, leading to sagging or even collapse. Unstable shelving poses a significant risk to both the stored items and anyone in proximity.

Risk of Collapse:

The most serious consequence of inaccurate measurements is the increased risk of a shelving unit collapse. Misaligned connectors may not distribute weight evenly, creating weak points that can fail under the stress of heavy loads. A collapsed shelving unit not only causes damage to stored items but also poses a potential safety hazard to individuals in the vicinity.

Safety Hazards:

Inaccurate measurements can compromise the overall safety of the storage area. Unstable shelves may pose a risk of falling items, potentially causing injuries to individuals working nearby. Moreover, a collapsing shelving unit can result in accidents and injuries, posing a direct threat to the well-being of those in the vicinity.

Reduced Storage Capacity:

Inaccuracies in measurements can lead to inefficient utilisation of space. Shelving units that are either too small or too large for the intended storage area may result in wasted space or insufficient capacity. This reduces the overall functionality of the storage system and hinders its ability to meet the needs of the user.

Damage to Stored Items:

Misaligned connectors can cause shelves to tilt or warp, leading to uneven weight distribution. This uneven distribution can result in damage to stored items, especially those that are fragile or sensitive to pressure. The primary purpose of shelving is to protect and organise items; inaccurate measurements can undermine this objective.

Operational Disruptions:

An unstable or unsafe shelving unit due to inaccurate measurements may require frequent adjustments or, in extreme cases, complete disassembly and reassembly. These disruptions can hamper daily operations, leading to downtime and potential delays in accessing stored items.

Increased Maintenance Costs:

The consequences of inaccurate measurements may necessitate additional maintenance and repairs. Regular adjustments or replacements of components become necessary to address stability issues. This incurs additional costs in terms of time and resources that could have been avoided with accurate measurements initially.

Compromised Aesthetics and Organisation:

Inaccurate measurements can result in a shelving unit that needs to be more cohesive and organised. This affects the storage area's aesthetics and undermines the intended organisational benefits of shelving systems.

To mitigate these consequences, it is crucial to prioritise precision in measurements during the planning and installation of shelving units. Following manufacturer guidelines, using accurate tools, and conducting regular assessments can help maintain the storage system's stability, safety, and overall functionality over time.

Read More: Why Boltless Shelving is a Game-Changer For Diverse Industries

Types of Shelving Systems on G-Rack

G-Rack offers diverse shelving systems designed to cater to various storage needs in different settings. From residential spaces to industrial warehouses, our shelving units are versatile, durable, and stylish, effectively keeping spaces organised and clutter-free. Explore the following types of G-Rack shelving systems.

Buy 5 Tier Boltless Shelving Unit | 180 X 90 X 40 cm

Boltless Shelving

G-Rack's boltless shelving units are designed for easy assembly without the need for nuts and bolts. These versatile 5-tier shelving systems provide robust storage solutions, making them ideal for sheds, garages, and home corners. The boltless design ensures quick setup and reconfiguration as needed.

Buy Boltless Corner Shelf | 90 x 90 x 30 cm

Corner Shelving

G-Rack's corner shelving units are tailored to maximise storage in corners, utilising often underutilised spaces effectively. These units are perfect for optimising room layouts and creating efficient storage solutions in any setting.

Buy 5 Tier Heavy Duty Boltless Garage Shelving Unit

Garage Shelving

Specifically crafted for garage storage needs, G-Rack's garage shelving units are robust and sturdy. These units offer ample space to organise tools, equipment, and other items commonly found in garage settings. The design ensures durability and practicality in a garage environment.

Buy 5 Tier Boltless Pantry Shelving Unit (set of 2) | 150 X 75 X 30 cm

Pantry Shelving

G-Rack provides pantry shelving solutions to enhance kitchen organisation. These units are designed to store pantry items efficiently, ensuring easy access to food and kitchen essentials. The shelving systems contribute to creating a tidy and functional pantry space.

Warehouse Shelving

G-Rack's warehouse shelving systems are built to meet the demands of industrial storage. These heavy-duty units provide high load-bearing capacity, making them suitable for organising and storing inventory in warehouse environments.

Buy 5 Tier Boltless Industrial Shelving Unit (set of 4) Plus Workbench

Industrial Shelving

G-Rack's industrial shelving units are engineered for durability and strength. These robust systems are suitable for heavy-duty storage requirements in industrial settings, offering a reliable solution for organising tools, equipment, and industrial supplies.

Shelving with Workbench

G-Rack integrates functionality with its shelving units by offering designs that include a built-in workbench. This combination provides a versatile workspace and ample storage, making it ideal for workshops, garages, or areas where storage and workspace are essential.

Spares Shelving

G-Rack's spare shelving is designed for the efficient organisation of spare parts and supplies. These units offer adjustable shelving to accommodate items of various sizes, providing a systematic and accessible solution for managing spare inventory.

G-Rack's commitment to providing reliable, durable, and stylish shelving solutions extends across various applications. Whether you're organising a garage, warehouse, pantry, or industrial space, G-Rack offers versatile and high-quality shelving systems to meet your storage requirements. Say goodbye to clutter and embrace a well-organised and functional space with G-Rack shelving units in the UK.

Tips for Maintaining Shelving Stability

Ensuring the ongoing stability of shelving units is essential for maintaining a safe and organised storage space. Here are some tips for maintaining stability over time, along with suggestions for regular checks and adjustments.

Regular Inspection:

Conduct routine inspections of your shelving units to identify any signs of wear, damage, or misalignment. Look for bent or damaged components, loose bolts, or any visible issues that may compromise stability.

Weight Distribution:

Be mindful of the weight distribution on the shelves. Avoid overloading shelves or placing disproportionately heavy items on one side. Distribute weight evenly to prevent strain on individual components.

Use Appropriate Materials:

Ensure that the shelving components, including uprights, connectors, and shelves, are made of materials suitable for the intended load capacity. Follow manufacturer guidelines for weight limits and usage specifications.

Securely Fasten Connectors:

Periodically check and tighten all connectors, bolts, and nuts. Loose fasteners can lead to instability over time. Use the appropriate tools to secure all connections, and consider using locking mechanisms if available.

Align Uprights and Shelves:

Check that the uprights and shelves are properly aligned. Misaligned components can compromise stability. Use a level to confirm vertical alignment and adjust as needed.

Adjust for Environmental Changes:

Be aware of environmental factors, such as temperature and humidity changes, that may impact stability. Adjust shelving as needed to accommodate any shifts in the storage area.

Monitor for Sagging Shelves:

Keep an eye out for sagging shelves, especially in long-span shelving units. Reinforce shelves with additional support if necessary. Consider using support brackets for shelves or reinforcing beams to prevent excessive bending.

Regular Cleaning:

Clean shelving units regularly to remove dust and debris. Accumulated dirt can add unnecessary weight and may contribute to instability over time. A clean shelving unit is more accessible to inspect and maintain.

Reinforce High-Traffic Areas:

Identify and reinforce high-traffic areas where shelves may experience more stress. Reinforce these areas with additional supports or choose heavier-duty shelving units for increased stability.

Follow Manufacturer Guidelines:

Adhere to the manufacturer's assembly, usage, and weight limit guidelines. Follow the recommended maintenance practices outlined in the product manual to ensure the longevity and stability of the shelving units.

Document and Track Changes:

Keep a record of any adjustments or modifications made to the shelving units. This documentation can serve as a reference for future inspections and maintenance, helping to identify patterns or recurring issues.

Professional Inspection:

Consider scheduling periodic professional inspections, especially for large or complex shelving systems. A professional can assess the overall stability and identify potential issues that may not be immediately apparent.

Incorporating these tips into your regular maintenance routine can contribute to your shelving units' long-term stability and safety. Regular checks and adjustments will help identify and address issues before they escalate, ensuring a reliable and durable storage solution over time.

Key Takeaways for Optimal Shelving Performance

When it comes to optimising storage solutions, wall shelf brackets and boltless racking systems play a crucial role in creating functional and efficient spaces. The innovation of adjustable shelf brackets allows for customizable storage configurations, catering to the diverse needs of users. Boltless shelving upright connectors further enhance the structural integrity of these storage units, ensuring stability and durability. The integration of these components not only simplifies the assembly process but also provides a versatile and adaptable storage solution. Whether organising a garage, warehouse, or office space, the combination of wall shelf brackets, boltless racking, adjustable shelf brackets, and boltless shelving upright connectors offers a seamless and reliable storage solution for a wide range of applications.

G-Rack UK is a brand that understands the importance of accurate measurement in creating high-quality and reliable shelving units. Their products are designed with precision in dimensions, weight distribution, and alignment to ensure that their customers enjoy sturdy and safe shelving options for their homes or businesses.

When considering shelving solutions, it's essential to prioritise accurate measurements to guarantee optimal performance. With G-Rack's attention to detail in its products, customers can be assured that their shelving units will be able to withstand the test of time, providing a functional and efficient space that is organised and inspiring.

FAQs

Do different shelving systems require different measurement techniques?

Yes, different shelving systems may require varied measurement techniques. The design and construction of each system, such as boltless, corner, or industrial shelving, can influence the specific measurements needed for accurate installation.

How do shelving joints differ from connectors, and when should each be used?

Shelving joints refer to the points where different components come together, while connectors are separate pieces used to join elements. Joints are integral parts of the shelving structure, whereas connectors are additional components. Use joints for inherent connections and connectors for added stability or customisation.

Do I need professional help for measuring and installing upright connectors?

While DIY measurement and installation are possible, complex shelving systems or industrial settings may benefit from professional assistance. Professionals can ensure precise measurements and correct installation, especially in large-scale or specialised applications.

Are racking connectors interchangeable between different shelving systems?

It depends on the design and specifications of the connectors. Some connectors may be interchangeable between similar systems, but variations in design and size can limit interchangeability. Always check compatibility with the manufacturer's guidelines.

Can I reuse upright connectors for a different shelving unit?

Reusing upright connectors depends on their condition, design, and compatibility with the new shelving unit. Ensure that the connectors meet the specifications of the new system and are structurally sound for safe reuse.

Do bay connectors serve a specific purpose in shelving units, or are they optional?

Bay connectors are crucial for the stability of shelving units, providing lateral support between bays. They are not optional in systems where bays need to be connected. Using bay connectors ensures the overall integrity and strength of the entire shelving structure.

What materials are used for shelf uprights in metal shelving units?

Shelf uprights in metal shelving uprights are commonly made from materials such as steel or aluminium. These materials offer durability and strength, essential for supporting heavy loads in industrial or commercial settings.

Are there specific weight capacities associated with different racking uprights?

Yes, different racking uprights have specified weight capacities based on their design, materials, and intended use. It's crucial to adhere to these weight limits to ensure the safety and stability of the shelving system.

Can I replace individual shelf uprights, or must I replace the entire unit?

In many cases, individual shelf uprights can be replaced without replacing the entire unit. However, compatibility and design considerations are essential to ensure the replacement uprights fit seamlessly with the existing structure.

Do racking connectors play a role in preventing the wobbling of shelves?

Yes, racking connectors contribute to the stability of shelves by connecting uprights and preventing wobbling. They help distribute weight evenly and ensure that the shelving unit remains sturdy and secure.